Posted on Oct. 11, 2019

Hello.

I will describe carbide rotary files today.

Rotary files are made of high quality cemented carbide, which allows them to be used to machine a wide range of materials with different degrees of hardness. Files work with simple pneumatic and electric grinders. The guarantee of long-term operation is ensuring proper rotational speeds, hence the files are not suitable for working with drills. Rotary files come in a variety of shapes and sizes, rounded milling cutters, 90 degree cones, spherical, flame and pointed pointed mills are available. Most often, the gripping part is a six-millimeter mandrel.

Metal files are used for removing hail, enlarging holes and grooves, smoothing welds and joints, processing irregular holes, chamfering edges.

The file can be cut in various ways. Teeth types depend on the material being processed.

Single-cut carbide files are used for general use for machining soft materials, cast iron, copper, bronze and brass.

Carbide files with a double cut. The chip breaker allows for quick removal of allowance in hardened hard materials, the breaker gives a short chip and excellent surface finish, small chips help eliminate the load on the blades.We have these files in stock, because they are most often used.

For all rotary files, unlike hand files, the scale is not given as the number of whole teeth per unit length of the file, measured in the direction of its length. The working speed for the material is given.

File attachment in the holder must be stable and make up 2/3 of the length of the handle. Before mounting, check the chuck for metal particles and blow if necessary. During work, check whether the milling cutter does not slip out of the holder due to rotation. Milling only in the opposite direction, milling cutters with soldered carbides are sensitive to vibrations. If it gets vibrations, it will break teeth or even the whole head may break off.

The contact surface of the blade with the workpiece during processing should be max. 1/3 of the tool circumference.

For difficult-to-cut materials, the cutting data must be reduced to prevent early wear of the tool.

During processing, remember to comply with health and safety regulations, especially safety glasses and neck protection against filings. A practical way to eliminate swarf may be to use a magnet, e.g. a magnetic angle such as for welding.

Do you want learn more details about carbide burr, please contact us!

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

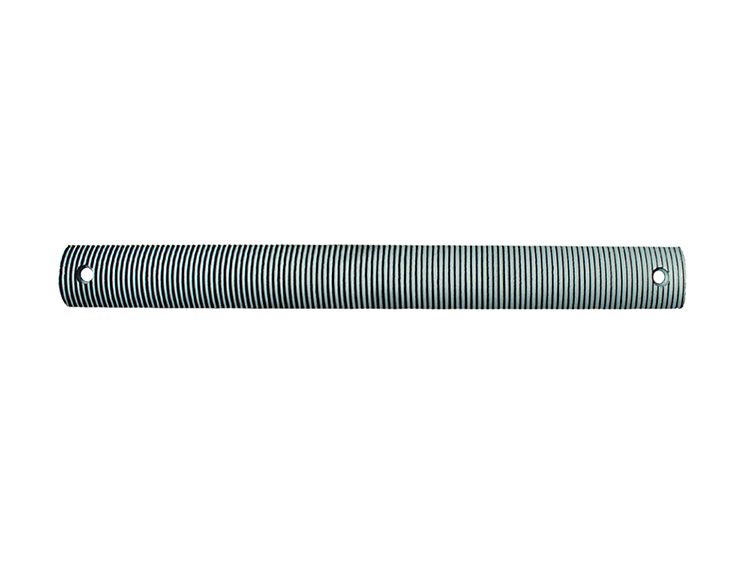

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

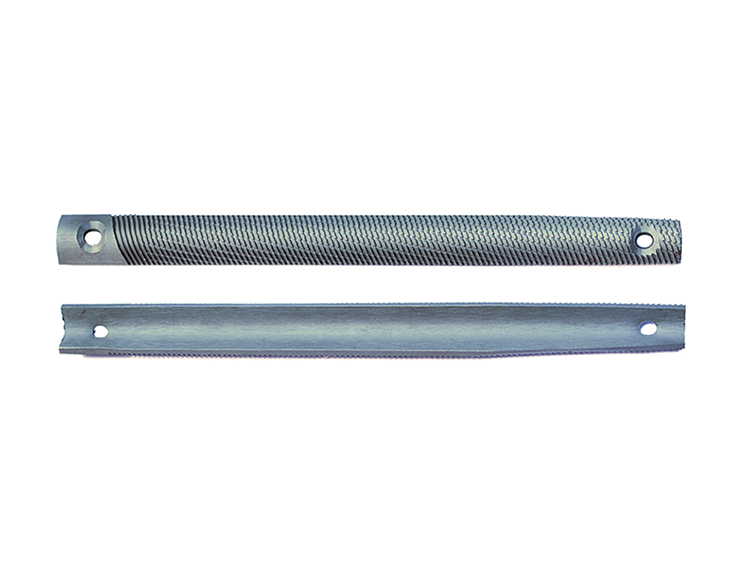

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

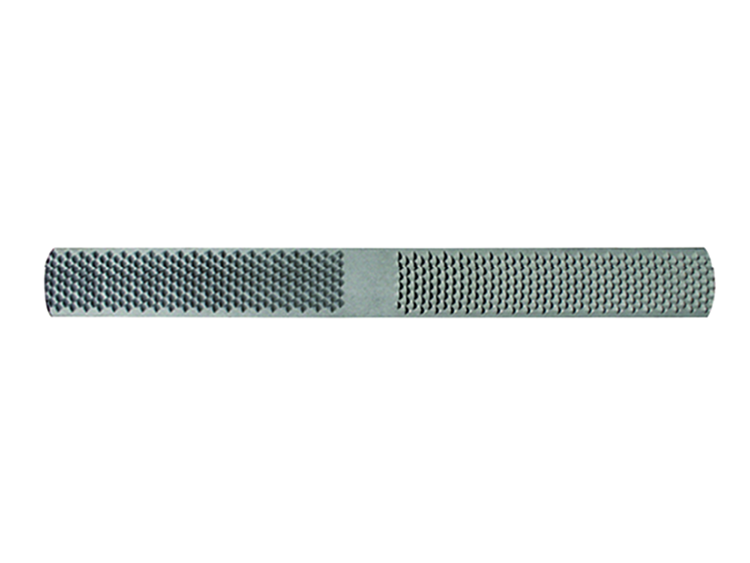

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: