Posted on Aug. 06, 2019

When you choose the carbide burrs, will you have this question, should i choose HSS or Carbide material?

So let’s tackle that forest of burs and cut them down to size. Burs come in different metals, shapes, and sizes. But which one is best for my job?

Actually, our burs can be separated into four main categories: high-carbon, high-speed steel (HSS), carbide and diamond. All of our burs are high-speed, by the way. ‘High-speed’ in the name simply tells you that, at speed, with the friction and heat that is generated by the work, the bur will maintain its temper. But, keep in mind that some burs will perform better at high speeds and some at low speeds.

Here is a quick and comprehensive list of characteristics of alloyed steel:

Hardness---- the steel’s basic Rockwell scale or the ability of the steel to resist permanent deformation

Heat Resistance– the steel’s ability to maintain its temper at high temperatures

Strength– the steel’s ability to resist applied force

Toughness– the steel’s ability to absorb energy before actually breaking

Ductility– the steel’s ability to flex or bend without cracking

Temper-ability– the steel’s ability to be hardened or tempered

Wear Resistance– the steel’s ability to resist abrasion (important when dealing with sharpening)

Corrosion Resistance– the steel’s resistance to oxidation (rust)

Edge Retention--the steel’s ability to maintain an edge (not the same thing as wear resistance!)

Ability to Take an Edge– the ability to put an edge on it (fine-grain steels generally take an edge much better than coarse grain steels)

Depending on the alloy/steel combination, burs will have some of these qualities more than others. While considering the different options, it is helpful to keep in mind that the most expensive bur does not mean that it is going to be the best one.

Let's check HSS first:

High Speed Steel (HSS) is also high-carbon tool steel, containing a large dose of tungsten. A typical HSS composition is: 18% tungsten, 4% Chromium, 1% Vanadium, 0.7% carbon and the rest, Iron. HSS burs maintain temper despite the friction and heat that is generated by the work.

HSS can be heat treated to a very high hardness. This, combined with wear resistant carbides, creates a very good edge retention and abrasion resistance. One limitation of HSS is that its usable cutting speed range is lower when compared to carbide. The advantages of HSS over carbide are its strength to withstand cutting forces and the low cost of the tools. They also require less maintenance than the high-carbon burs since they are less prone to rust. From the tool life point of view, HSS is tougher than carbide and will last a longer time.

Then Carbide burr

Carbide burs are three times stronger than any steel. They are heat and wear resistant.

Tungsten and vanadium increase strength in steel by forming carbides. Other carbide-producing elements include chromium, titanium, niobium, molybdenum and cobalt. In order for a steel to be carbide steel it must contain at least 1% of the carbide-producing element. A carbide tool has an equal number of carbide producing element as carbon atoms.

Carbide burs are great for cutting carbon steel or stainless steel and can be conveniently cleaned with a propane torch. The only downside to this metal is that, due to its high hardness, it is brittle and can chip or shatter more easily than other materials.

Burs made with this material are great for soft metals such as high-karat gold and platinum because they are very strong and precise but unlikely to chip or break on the softer metals. These burs are very durable and as long as they don’t chip will last a long time. They can also be used for longer production runs and cut with much less effort. Carbide burs can be used for deburring, finishing, smoothing, shaping, and carving many types of materials. Carbide slices or chips away at material leaving a smooth surface. But they can still be effective on harder metals. It is best to use these at high speeds with light pressure.

Which one should you use for your particular material?

Overall, the best metal for the job depends on how much you will use the burs—and on personal preferences such as whether you prefer more durability or more edge. Do you prefer less maintenance? Will they be used intermittently or continuously, at high speeds or low speeds? It also depends on how often you will use them. Many times it is mostly a matter of preference. Perhaps you would rather use less pressure and a carbide bur might be too powerful or aggressive for you. The carbides do tend to be more aggressive due to the larger teeth on most of them.

Here is a chart to help you decide which bur is best for this two materials:

I hope this information gives you a better idea of which bur material will be best for the jobs you need to do.

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

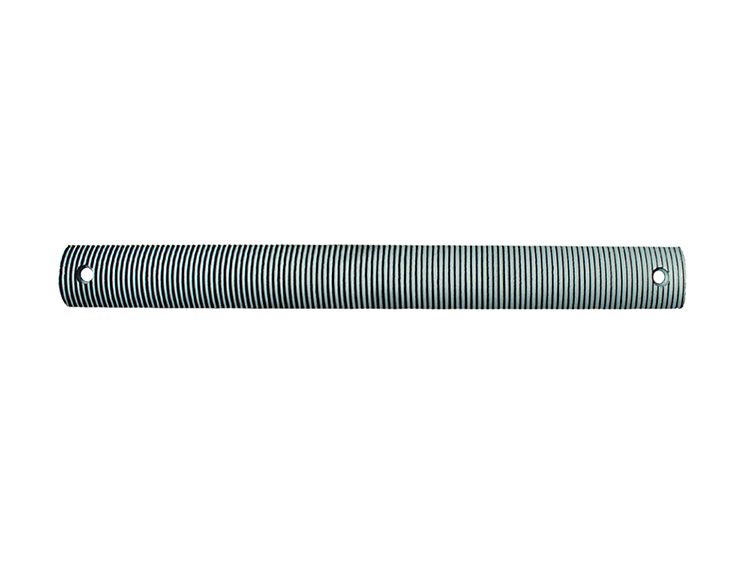

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

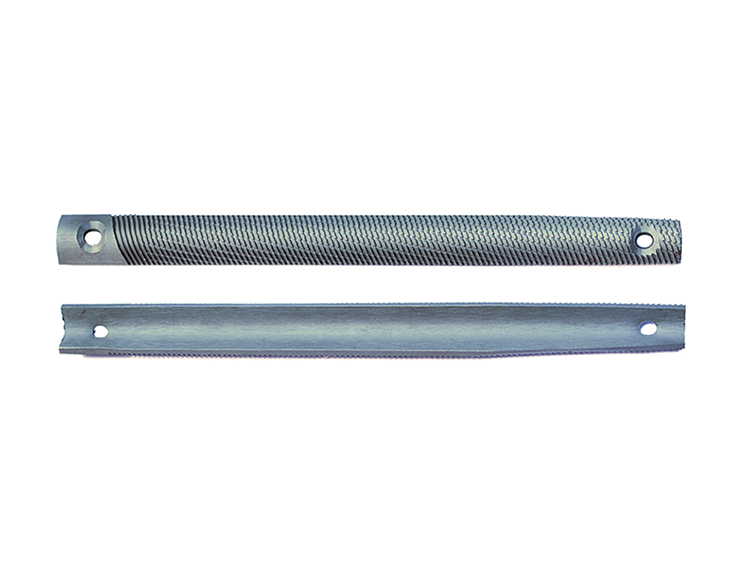

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

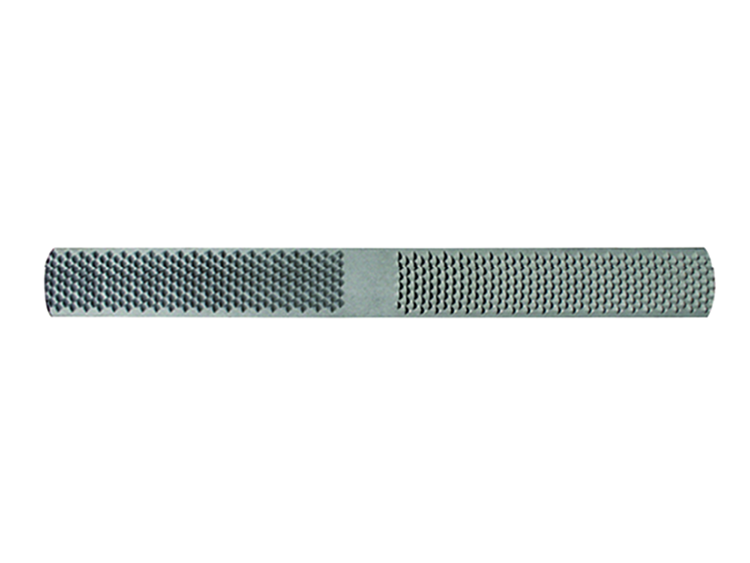

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: