Posted on Nov. 15, 2019

Carbide burrs are used for roughing and finishing metals - deburring, deburring welds, and finishing complex surfaces.

On the surface of the part after operations such as casting, cooking, sawing, drilling or milling, nicks or irregularities may remain. Burrs effectively remove such burrs, leveling the surface.

It is the carbide that provides the high resistance of the burr cutter and allows to accelerate the processing process.

But how to increase the life of the burr?

Improper use threatens to worsen the burrs, as well as the risk of spoiling the equipment. To avoid this, follow a few simple guidelines:

To use the cone most effectively, ensure full contact of the working part and the metal.

Make sure that the product and tail are not in contact. Otherwise, the burr cutter may become unusable.

Do not push too hard: efficiency will decrease, and the equipment will receive more load. Because of this, there is a great chance of overheating.

To eliminate bumps and jamming, operate at high speeds.

Use grease. This will improve gliding, as well as reduce the load on the cone. For example, to reduce wear on the cutting part, you can use the suspension by dipping a tool into it.

Replace the burrs on time - otherwise you will have to apply a lot of effort to the tool. This creates a risk of equipment breakdown.

Any question, please contact us!

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

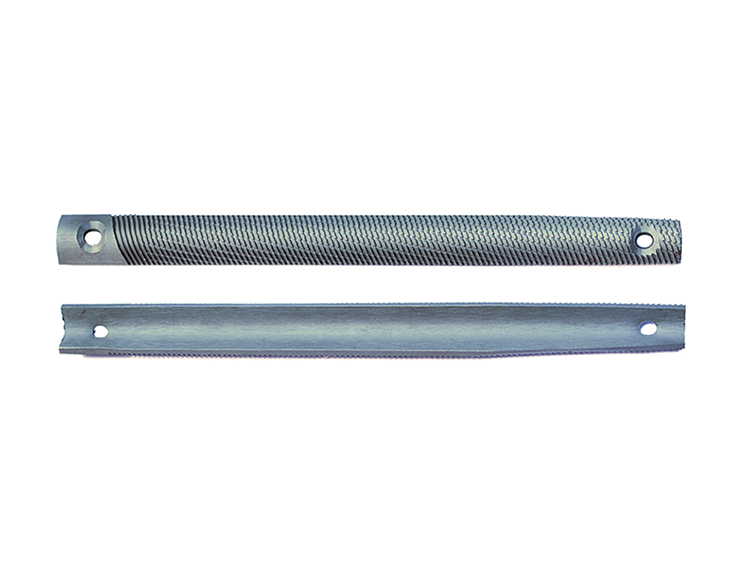

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

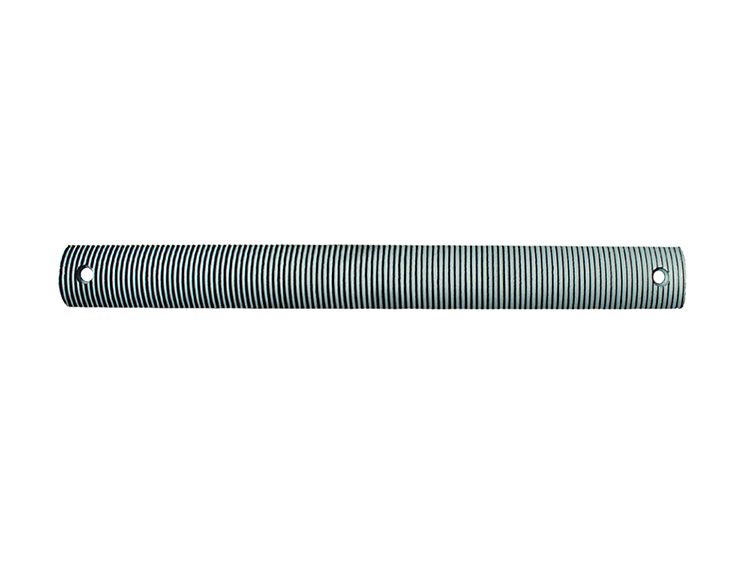

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

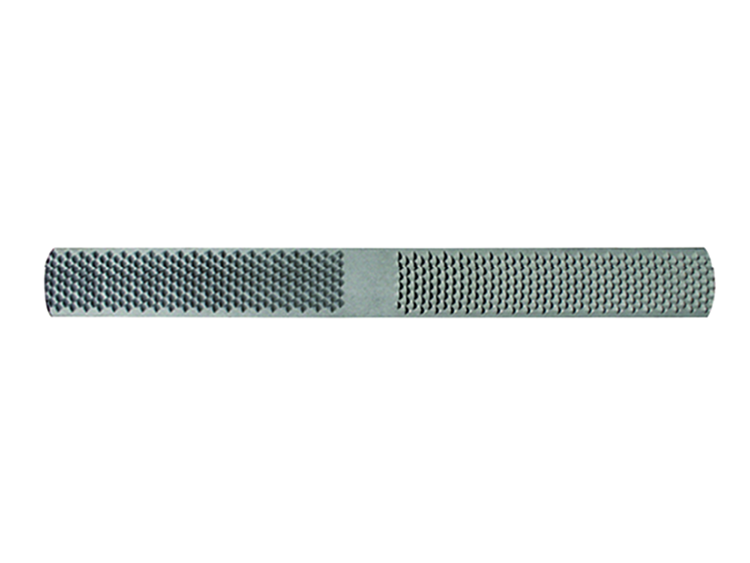

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: