Posted on Sep. 28, 2021

1. There are burrs on the teeth of the new file. If you use a file to cut hard metals, the burrs will be worn off and the file will be blunt early. Therefore, you cannot file hard iron and steel with a new file.

2. Do not use new files to file the iron oxide or cast crust surface and unannealed hard steel parts. The iron oxide and cast crust must be ground off on the grinding wheel first, and the old can only be used if it is not allowed. File off with the file.

3. Do not use fine files to file soft metals (lead, tin, etc.), because the file layer of soft metal is easy to be embedded in the tooth grooves of the teeth, and the file will slip on the surface of the workpiece.

4. Do not stack files together to avoid damage to the teeth.

5. Do not make the file wet or place it in a damp place to prevent corrosion.

6. When filing soft metal, the teeth of the file are often blocked by the file layer. At this time, the file layer can be brushed off with a wire file brush. In order to avoid the teeth of the file being blunt by the wire brush, brush the wire brush to the hooked side of the wire along the direction of the file tooth. If the large file is embedded, it should be scraped off with a copper scraper, but it must be removed in the direction of the file tooth

Wood Rasp 3 Set American Pattern Flat Half Round And Round

Wood Rasp 3 Set American Pattern Flat Half Round And Round  American Pattern Wood Rasp 5 Set Flat Half Round Square Roun...

American Pattern Wood Rasp 5 Set Flat Half Round Square Roun... American Pattern Steel File 3 Set Flat Half Round And Round

American Pattern Steel File 3 Set Flat Half Round And Round Steel File 5 Set Flat American Pattern Half Round Square Rou...

Steel File 5 Set Flat American Pattern Half Round Square Rou... 14inch Double Aluminum Semicircle Filing Medium

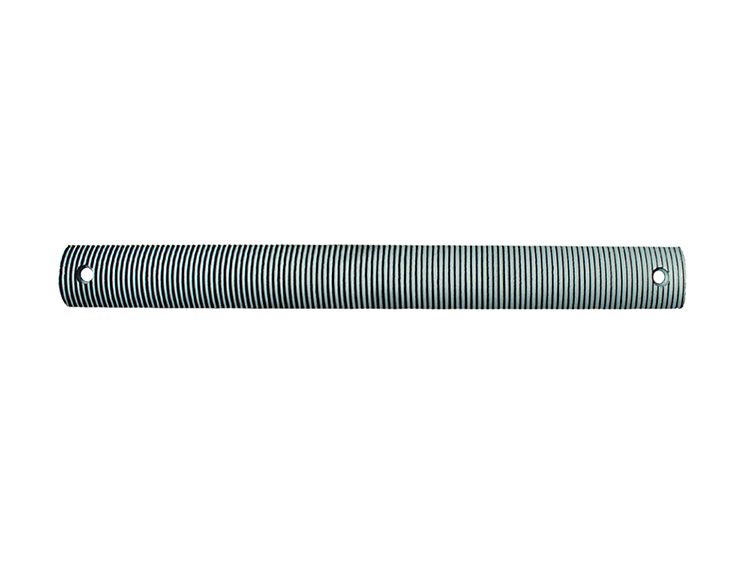

14inch Double Aluminum Semicircle Filing Medium Helical Hollow Aluminum Semicircle File Hand Tool Medium

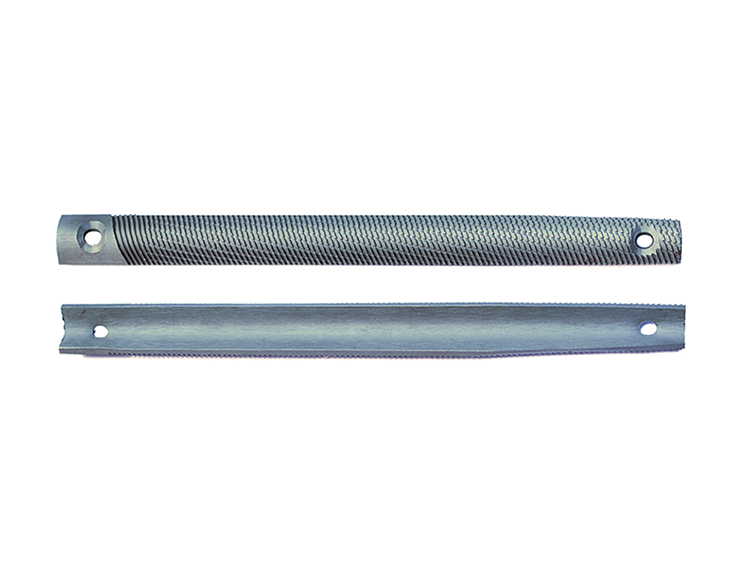

Helical Hollow Aluminum Semicircle File Hand Tool Medium 14inch Double Horseshoe Files Horse Rasps Double Cut

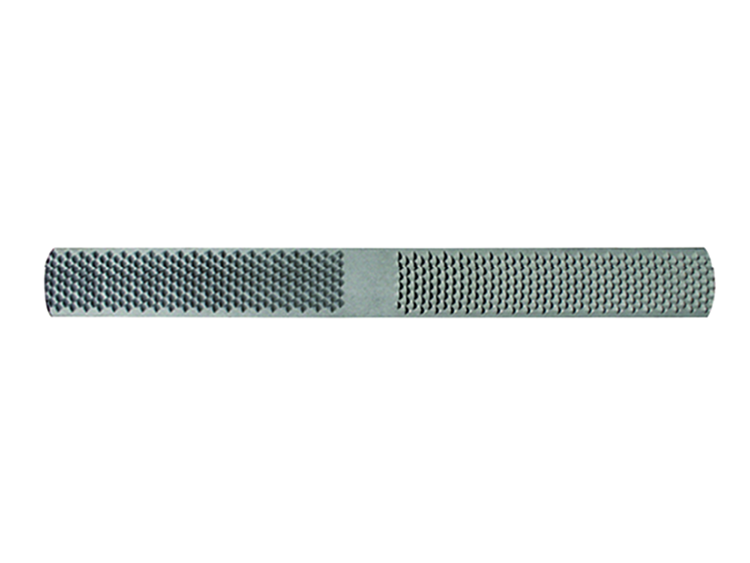

14inch Double Horseshoe Files Horse Rasps Double Cut 14inch Horse Rasps Horseshoe Files Double Cut

14inch Horse Rasps Horseshoe Files Double Cut

Copyright © Nanhe Ruixin Tools Co., Ltd All Rights Reserved.

Sitemap | Technical Support: